Before, Shenzhen is more often associated with inexpensive manufacture than with Product Development. However, it makes more sense to not only manufacture in Shenzhen but also design and development your product here today. Turn-key product design and manufacturing in Shenzhen China , you benefit from cost effective, including of Shenzhen high precisely molding, qualified processing and electronic total solution, module and components. All of these advantages can be utilized in your device to help lower your unit cost. But to do that, you need designer and engineers adept at designing with modules and electronic solution made in China, need designer and engineers adept at designing with molding made in China, and that is where we excel.

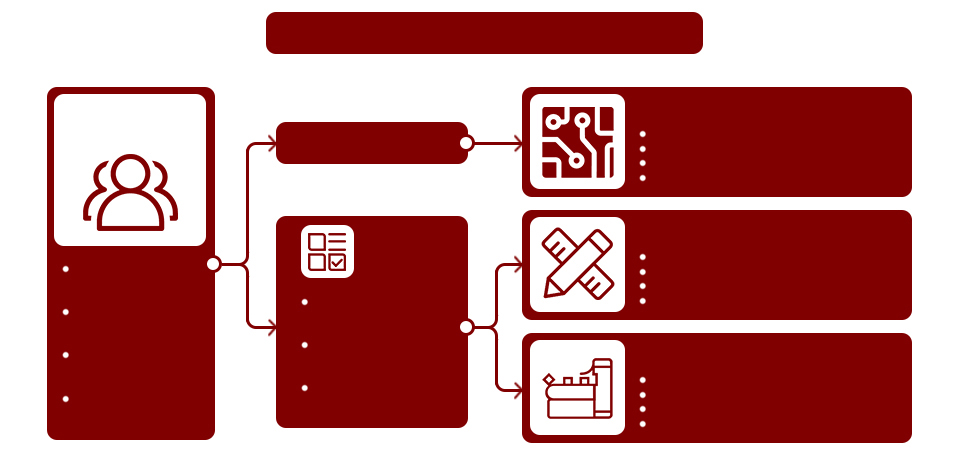

Turn-key Product Design and Manufacturing in Shenzhen China

Turn-key product design and manufacturing is a complex process that requires a concerted effort of managing a project through the various stages of development. We specialize in turning your product into a market-ready reality. We have already dedicated in this field over 10 years. In the past years, we successfully co-work with customer to discuss and resolve all related of design and manufacture task, leverage low cost internet communication. Help our clients can finish their product development and manufacturing in China at high efficient and low cost, but finish final assembly in its local country. It is called End-to-End Turn-key Product Design and Manufacturing.

A Good Start

Our product development and product design services are firmly rooted in our experience in product manufacturing. Collaboration between our designers, engineers, and manufacture suppliers allows us to consider the design effects during manufacturing phase at very early stage. As a result, you benefit from a product that is designed for successful mass production from the beginning and take advantage of cost reduction, reduced risks, and a shorter time-to-market.

Diversified Design Service and Technical Integration to Meet Your Demand

To know more details

- What if you come to us for making a target product with only electronic solution. Our industrial designer will take input from the initial stage and begin conceptual renderings and studies. The designer will also collaborate with the engineers from the start to define design boundaries and guidelines for manufacturing and electronic design; this leads to reduced risks and a shorter time-to-market later.

- What if you come to us for making a product with your already existing ID. Our engineers will proceed with mechanical design base on the electronic boundaries and manufacture guidelines. Finally ensure your ID can be implemented into real product stage.

- What if you come to us for making a new concept product without electronica solution yet. Because, we are not expert on any electronic solution, we need to evaluate your function and requirements firstly. Sometimes, we still can help to source it from Shenzhen diversified electronic solution resource base.

- What if you come to us with only one part. You had met the challenge on sourcing professional supplier to design or produce it. It might be the problem of surface processing, accuracy consistency and unusual material. Our engineers are also able to process it base on Shenzhen diversified manufacturing resource base, with extensive experience, on-site technical communication, monitor and checking in-time to finish the hard task.

To define the scope

We would like you provide your demand, product requirement and preparation, then, we can understand what we can do for you. Most of customers need the two kinds of service.

A: ID + MD design + Molding design + Enclosure manufacture

B: Specially Mechanical Parts Molding Service

Study and Pre-design

Clarify your requirements on usability and function, the principle operations of the entire product and main electronic components selected.

If you are in this field where we have ever already served as above, we are familiar with your product and understand your demand at the first time.

Especially for concept product, sometimes, we need to source more solutions from a technical standpoint for certain project to determine whether the concept or product can be realized for commercial.

Then, an analysis will be performed to ensure that they are in line with your business plan from the standpoint of features, manufacturing, price and competition.

Industrial Product Design

We are designer and we are well versed in designing for maximum marketability as well as for optimal manufacturing.

Design for The Balance.

The value of a good industrial design is clear: an attractive design not only helps to sell more products, it also allows you to charge higher prices. So simply thinking design is about esthetics—if your product does not look appealing, it will not sell. However, esthetics alone do not guarantee success.

Actually, careful consideration of production in the initial stage is crucial in product design, as a sizeable percentage of the product’s lifecycle cost is committed at this time (cost of materials, production of parts, and assembly). So the much more important is balanced design. Balance the inspiration and realization, balance the material and finishing, balance the profile and structure, balance the total design and total cost… The value of a balanced industrial design is much more important than only esthetics.

Successful product Development is a complex process. It needs desinger and engineer to cooperate in different industry fields. Balance them and how to balance design is very important through entirely product development progress.

We keep the perception to customer’s original requirements, to discuss with customer, to help them simplify the complex design objectives, to dig out the core requirement. Then figure out proper solutions systematically. Finally we convert the sparkling inspiration into clearer thoughts in mind, then realize them in a structured form with appropriate technologies, materials and finishing and create excellent products which are rich in commercial value.

We trust balanced design. What’s more, we have already successfully practiced into over hundreds of products.

- Less is More

- Make it easy for assembly

- Keep it Simple on surface finishing

- Keep it easy for molding

Mechanical Design

Working within the Balance and fulfill project objectives. We offer our customer the high quality design solutions that work within technical and price constraints

Our mechanical engineers are good at reconciling technical solutions with price and manufacturing constraints. This allows us to develop reliable mechanical systems and enclosures that are practical, cost optimized, and manufacturable at whatever production quantity at a very early stage in the development.

Our mechanical engineers have amassed years of experience working on a variety of projects and tackling challenges brought about by each of the project’s unique requirements—how and where it will be used. We leverage and build on this knowledge to the projects we take on and deliver solutions that impact the overall success of a product. To ensure that the most suitable design, material, and manufacturing process is selected and thus warrants the most optimized cost structure and performance of the product. A good mechanical design is crucial in the development of any electronic product. Mechanical engineering has direct bearings on

- The robustness of the enclosure and parts

- Material selection

- The manufacturing process

- Mold design and ease of plastic injection

- Cost of production

- Heat dissipation

- The reliability and life-span of movable parts

- Water and dust (IP) resistance

- Accessibility for maintenance and repair work

Prototype Verification

To develop electronic and mechanical prototypes. Prototypes are essential for usability, reliability, and functional validation. You will receive a prototype for your own testing and validation. While we will check the design real output, including of out-profile, dimension, assembly, mechanical performance and bring the prototype to a third-party lab (if required) .

Depending on the outcome of the assembly checking and test, refinements will be made to the product. Finally, all passed and go to mold making ready.

Molding and Pilot Run

To pilot run molding making plastic enclosures and metal.

After the first lot plastic and metal parts are produced, we check each part dimension to ensure that the parts comply with specifications. The electronics are placed into the enclosure for a fit check. If necessary, drop test will be performed.

Support oversea assembly.

We will help to organize all parts and standard operation process to guarantee stability of production and for further oversea assembly demand. Prepare SOP assembly video to help customer to train local employee to know how to assemble product correctly, quickly and how to check. Aside from material procurement, if require, manufacturing fixtures (jigs) will be made and procedures will be prepared for testing, and quality control. Finally ensure all parts meet the quality request and only need to do final and simple assembly at oversea.

From pilot run of 50-100units to formal mass production, we hand over to customer a simple executable solution for final product assembly at oversea.

Learn Who We Are

Learn more why we are Asia’s premier Product Development and manufacturing company.

Learn What We Make

See examples of project we’ve completed and know the industry we serve

Learn more about our company

Learn more why we are Asia’s premier Product Development and manufacturing company.